Nanotechnology helps control nanoworld processes and use its unique properties. This is a promising field of science that is turning into the basis for the development of new technologies. For example, scientists use carbon nanotubes to modify cells and their properties, apply nanotubes as capsules to deliver medicines, and create components for nanoelectronic and photonic devices. Apart from that, a “pinch” of nanotubes in concrete reduces construction costs and makes this material stronger. Below is our conversation with Head of the Laboratory of Carbon Nanomaterials at Russian New University (RosNOU) Olga Demicheva.

Olga Valentinovna Demicheva — Head of the Laboratory of Carbon Nanomaterials at Russian New University, Candidate of Physical and Mathematical Sciences.

— Olga Valentinovna, please tell us about the Laboratory of Carbon Nanomaterials of RosNOU. How did you decide to deal with nanotechnology studies?

— Our laboratory opened in 2008. This was the time when carbon nanotubes and carbon nanomaterials were booming. The scientific community was concentrated on carbon nanomaterials, which resulted in a large number of scientific publications.

RosNOU Rector Vladimir Alekseevich Zernov provided a special room with all necessary equipment, such as exhaust hoods, separate boxes, etc., for the laboratory.

The invited experts were facing serious challenges concerned with the most cost-effective synthesis of carbon nanotubes and their application. Such tasks had been previously solved by individual research institutes and institutions. Besides, it was necessary to connect the industry and specific laboratory R&D projects.

For this purpose, RosNOU established Small Innovative Enterprise Center of Nanotechnology focused on production of carbon nanotubes. The Center helped connect the production sector with science. Enterprises that need a nanoproduct turn to the Center of Nanotechnology. And we, in turn, perform specific tasks to create this product. In addition, we help put it into production.

Over these years, we have implemented many development projects, including those used in genetic engineering. For example, we have increased the productivity of plant genetic modification by dozens of times.

— What helped you achieve these results?

— Earlier, microscopic balls of gold were used to carry genes. The problem was that the balls were smooth and round. Therefore, genes did not adhere to them well enough, and gene modification was low-productive.

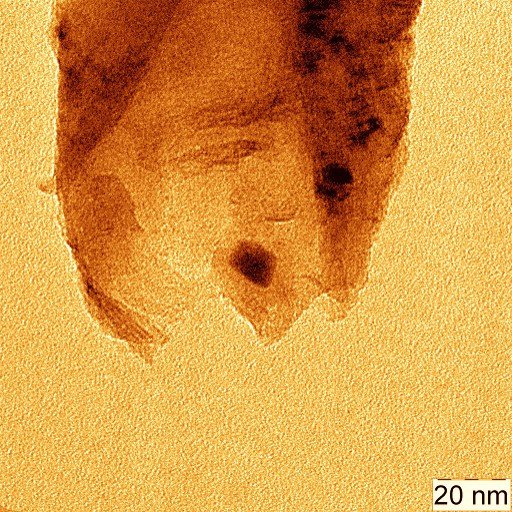

At our laboratory, we used short, hollow nanotubes with sharp ends. It turned out that a solution of specific genes penetrated into a nanotube very efficiently.

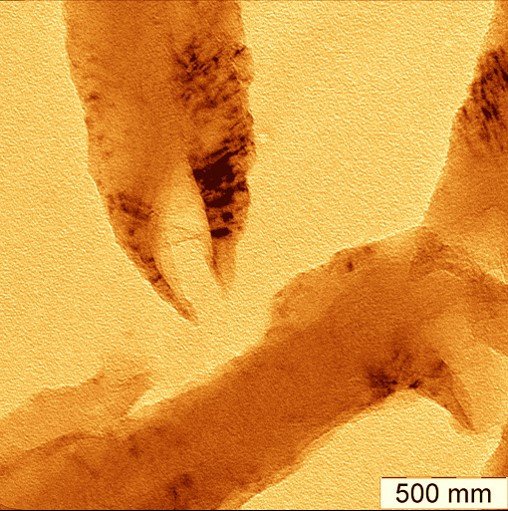

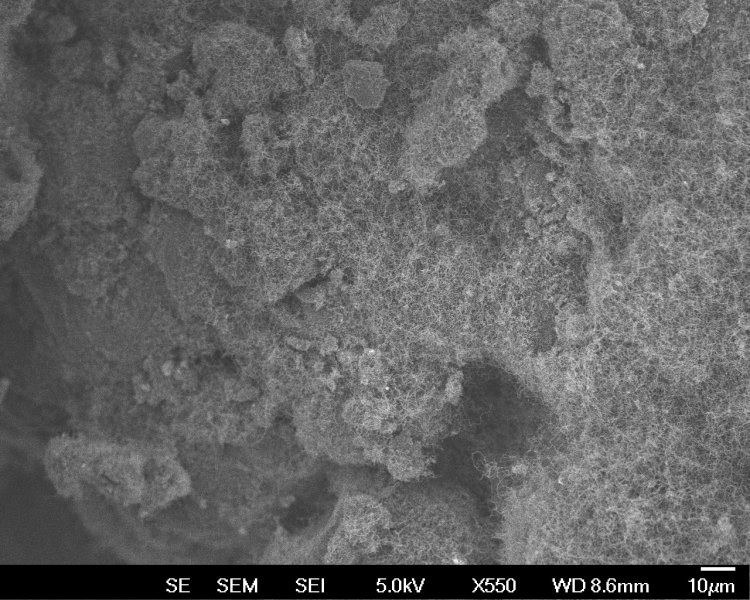

Types of ends of multilayer carbon nanotubes. Scanning electron microscopy

Types of ends of multilayer carbon nanotubes. Scanning electron microscopy

— Where are nanotubes used?

— In various sectors. They are used to produce construction materials, including concrete, adhesive compounds and compositions, in the paint and varnish industry, in medicine and agriculture. As for the latter, we used to actively cooperate with Russian State Agrarian University — Moscow Timiryazev Agricultural Academy (RSAU — MTAA named after K.A. Timiryazev).

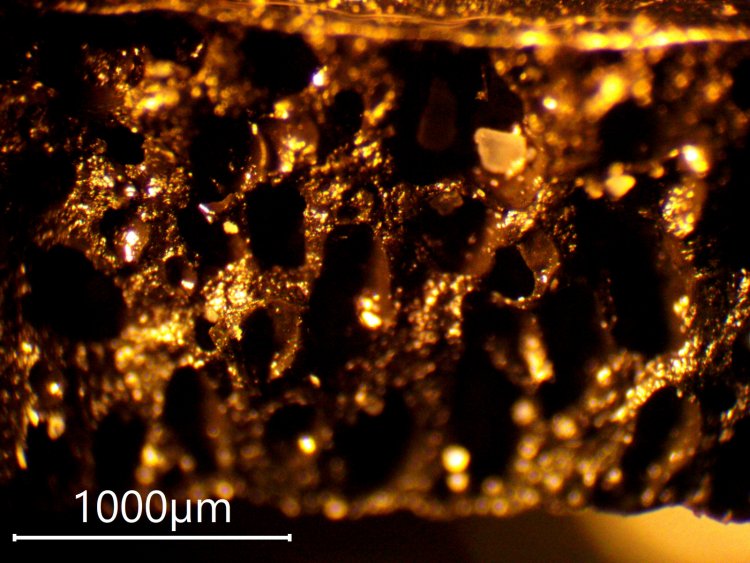

I should say that nanotubes are a very interesting thing, as they have both nanoscale and microscale. The length of a nanotube is several micrometers. Therefore, they can also transform any composite material at the microlevel. While a carbon nanomaterial added in a small amount changes the physical properties of large objects, such as concrete. If we introduce only 1 g of nanotubes and evenly distribute them over 1 m³ of concrete, we will get a composition suitable for building bridges, airdromes that require increased strength. Such concrete is resistant to moisture and frost. Its crack resistance grows, as the nanotubes “stitch” pieces of material at the microlevel to prevent cracks. Of course, such concrete can also be used in buildings to strengthen their foundation in earthquake-endangered areas.

Another unique feature of carbon nanotubes is that they are kind of a single molecule. Besides, they have unique electrical and thermal conductivity, like some other nanomaterials, such as graphene. Actually, nanotubes are a graphene sheet rolled into a tube. Thus, unlike graphene, they have a unique sorption property that makes it possible to use nanotubes in medicine.

Example of composite nanomodification. Pore size reduction from 5 mm to 100 µm upon introduction of nanotubes

Nanotubes are also used as containers — for example, to ensure safe transport of hydrogen. Owing to their high electrical conductivity, nanotubes can radically change the properties of this or that material — for example, protect it against static electricity. Nanotubes also effectively absorb light. Therefore, people add them to transparent paints and varnishes to prevent the negative effects of ultraviolet radiation.

— We are talking about nanoscale. How do specialists work with nanotubes?

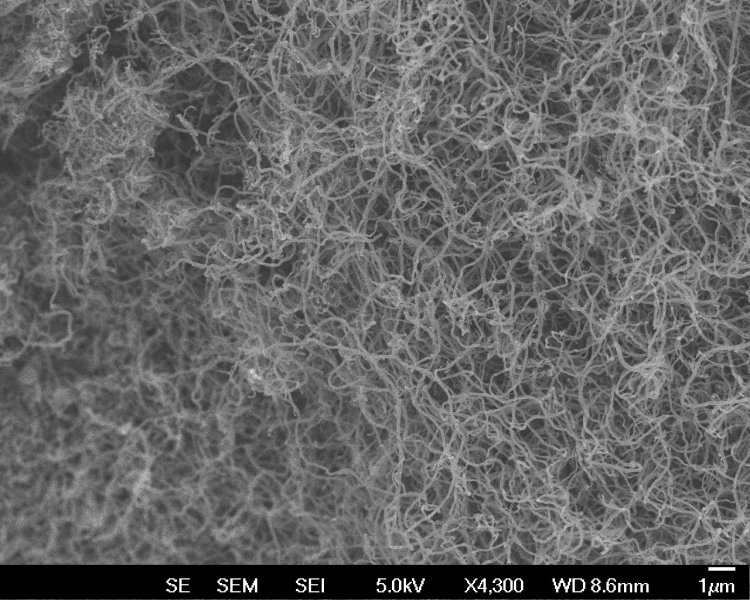

— Indubitably, to work with nanoscale objects, specialists have to make a lot of effort. Just imagine a fiber that is nanoscale in diameter and microscale in length. It resembles cotton wool with tangled fibers. What we do at our laboratory is specifically trying to make the process of working with nanotubes easier for the manufacturers who turn to us.

The first step is separating fibers. The next one is processing them to create a strong chemical bond with the manufacturer’s material. Or, conversely, prepare a dispersion of nanotubes in a solution to be used at a particular production facility.

The nanoengineering students of RosNOU having practical training at our laboratory actively participate in this work. Quite recently, our university introduced the Nanoengineering specialty and the first students will graduate in 2023. They have participated in industrial technology creation and done practical training at our laboratory.

— What tasks were they solving within their practical training?

— For example, one of the most interesting tasks is connected with the development of a method to apply carbon nanotubes in a micron layer of a transparent polymer onto an optical fiber. The thing is that when working with nanotubes, it is difficult to evenly distribute them over the surface and count them. Nanotubes are hydrophobic, i.e., they dislike water, and are inert, like any carbon. They do not connect with anything. Therefore, there is a need to find special techniques and select surfactants to dilute nanotubes and retain them in the entire volume of a solution. This is what our students have managed to do.

— You say that the research boom occurred in 2008. Can we state that scientists know everything about nanotubes today?

— No, of course, not. Nanotubes are constantly expanding their area of application, which triggers a huge number of scientific publications.

However, we talk about nanotubes significantly less often today, although breakthrough projects still exist at the moment. For example, those focused on nanoobjects combination. Quite recently, a combination of graphene and carbon nanotubes helped obtain carbon aerogel, a unique object with the lightest structure that is simultaneously able to withstand overload. Aerogel is highly elastic (it can recover its shape after repeated compression and stretching) and has an increased ability to absorb organic liquids. The latter property makes it possible to use aerogel, in particular, in oil spill response operations. Besides, the low thermal conductivity of aerogel based on graphene and nanotubes allows its use as a heat-insulating and fire-retardant material.

When listing the unique properties of nanotubes, I cannot but mention their electrical conductivity. Simply stated, they can withstand a very heavy charge. When we first started working with nanotubes, no one knew how to separate them. At our laboratory, we tried to place nanotubes on the copper substrate in a special box, as we believed that they would fly apart under the impact of a current pulse. However, when we supplied current and then opened the box, we saw that even the copper was not damaged. It means that nanotubes literally withstand a lightning strike and are used in lightning-protective composites. However, the most interesting, in my opinion, development projects are focused on creation of efficient solar batteries. Nanotubes are used not only to collect solar energy, but also to accumulate, store it, and ensure its instantaneous transmission.

— Which application of nanotubes do you consider the most promising one?

— I think it is aerogels. Today aerogel has been obtained only at the laboratory. Therefore, this is the most interesting target for future studies and industrial development.

— Does your laboratory work with aerogel?

— We have started developing an aerogel production technology. Our students accidentally found it one day without expecting that. The thing is that aerogel forms in a vacuum. When working on a composite material, they used vacuum to finally obtain something bubbly and airy, i.e., an aerogel prototype.

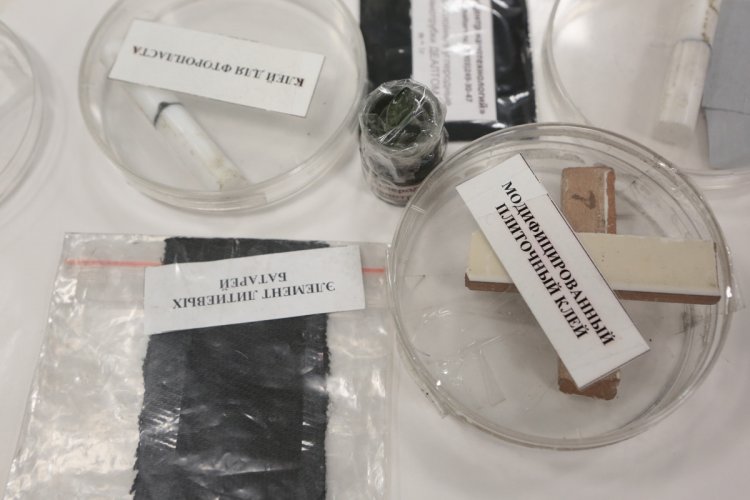

A 2.5 kg brick is supported by a piece of aerogel with a mass of 2 g

— What aspects of working with nanotubes would you draw the attention of the future RosNOU nanoengineers to?

— Today, the most interesting focus is at the intersection of their areas of application. Quite recently, scientists made attempts to obtain new materials based on nanotubes and nanocellulose. This area is practically unexplored. It requires serious fundamental studies. Specialists have only managed to create highly conductive paper based on them. Therefore, this area might be interesting to people studying carbon nanotubes.