Shchelkovo Biocombinat scientists on the production of vaccines against foot-and-mouth disease and other animal diseases. Photo source: Andrey Luft / Scientific Russia

Shchelkovo Biocombinat is one of the oldest and largest enterprises in the Russian agrobiological industry. Here they create vaccines against foot-and-mouth disease (FMD), brucellosis, and other dangerous animal diseases. Scientific Russia has visited its production site and learned the specifics of domestic vaccine manufacturing in veterinary medicine.

Shchelkovo Biocombinat is located in the Losino-Petrovsky urban district, Moscow region. It manufactures over 30 types of domestic products: medicines (vaccines) for veterinary use, diagnostic kits, etc. About 30% of products are exported to 20 countries.

Its specialists produce FMD mono- and polyvalent vaccines, rabies vaccines for all animal species, brucellosis vaccines for cattle and small ruminants, rhinopneumonitis vaccines for horses, vaccines for pigs, birds, and more: over a billion medicine doses per year in total.

“Shchelkovo Biocombinat was founded in 1924, so we are going to celebrate our centenary in a few years. We have managed to preserve the initial production capacity and further expand it. The enterprise has established scientific units that, among other things, create genetically modified and recombinant vaccines. Such vaccines are very sought-after in today’s market as they are more cost-effective in comparison with many other medicines,” says the Director of the Biocombinat Oleg Akilin.

Over half of all products are vaccines against especially dangerous infections, that is, FMD and rabies.

“FMD pathogen belongs to Risk Group 2, so biosafety requirements are tough here. The FMD production facility is completely isolated from the external environment and we use negative pressure in cleanrooms. These safety measures ensure that the virus cannot leave the production site,” says Candidate of Veterinary Sciences, Deputy Director Vasiliy Elnikov.

Deputy Director of Shchelkovo Biocombinat Vasiliy Elnikov. Photo: Andrey Luft / Scientific Russia.

FMD is one of the most dangerous and contagious diseases that causes huge economic damage to the livestock industry. The disease affects not only cattle and small ruminants, but also pigs, buffalos, deer, and camels. In animals, FMD manifests itself in the form of aphthous ulcers on the mucous membranes of tongue, lips, gums, as well as on udder skin and in interhoof gap. However, immunization with one type of the FMD virus does not protect against other types. Besides, each virus type has strain-related differences making the prevention of this dangerous disease more challenging. Therefore, vaccination is crucial in potentially vulnerable areas.

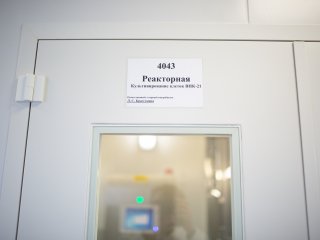

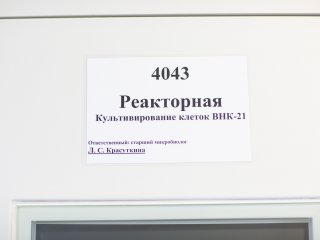

“To produce vaccines, we use the inactivated or ‘killed’ FMD virus. We cultivate the FMD virus in suspended BHK-21/13–13 cells,” explains Vasiliy Elnikov.

The vaccines are produced with domestic equipment. Bioreactors that grow cells are cleaned and sterilized automatically. Computers show real-time production process parameters and archive them. Thus, experts can always analyze the production process and make adjustments accordingly.

“We usually use culture media that contain animal products, including bovine serum for the cultivation of rabies and FMD virus cells. However, we have recently focused on another promising direction, that is, the use of serum-free nutrient media that do not contain bovine serum. This new approach will help to eliminate the risk of cell contamination (from Latin “contaminatio” — contamination as a result of contact, mixing; contamination of one substrate or biological material with another. — Editor’s note) with prion infections during cultivation. When selecting a serum-free nutrient medium, we test both Russian and imported products,” says Ilya Stoyanov.

Reactor hall of Shchelkovo Biocombinat. Photo: Andrey Luft / Scientific Russia

Shchelkovo Biocombinat has over 600 professionals: veterinarians, microbiologists, biotechnologists, biochemists, engineers, laboratory assistants, etc. International Good Manufacturing Practice (GMP) standards have been introduced at each vaccine production stage.

The immediate goal of the scientists is to create import-substituting medicines for veterinary use. Over ten of them are already under development. The experts create new products both independently and in cooperation with the leading biotechnological research institutes of Russia.

See our videos to learn more about the work of the Biocombinat.

Comment by antiviral production technologist Ilya Stoyanov.

Comment by Deputy Director of Shchelkovo Biocombinat Vasiliy Elnikov.

Comment by Senior Microbiologist at Shchelkovo Biocombinat Olga Loivskaya.

Story sponsored by the Ministry of Science and Higher Education of the Russian Federation and the Russian Academy of Sciences.