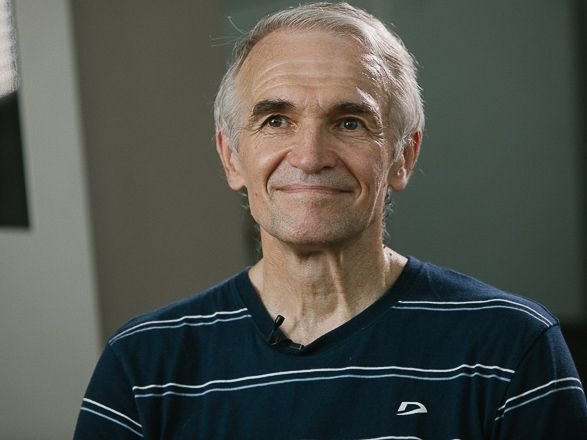

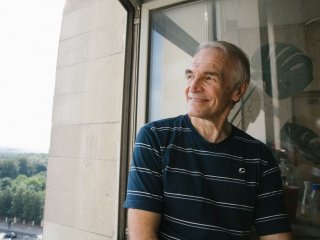

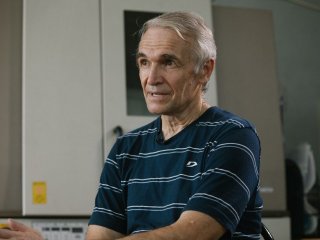

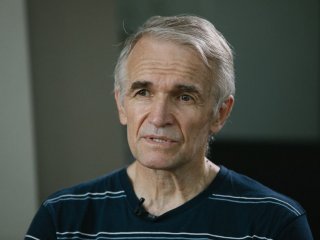

How can we provide for the future energy needs of humanity? Can we hope for hydrogen energy? How to find a reasonable balance between growing needs and maintaining a healthy environment? We talked about this with Andrey Borisovich Yaroslavtsev – Corresponding Member of the Russian Academy of Sciences, Head of the Laboratory of Functional Materials of the Institute of General and Inorganic Chemistry, Head of the Laboratory for the Study of Catalytic Processes on Membranes of the Institute of Petrochemical Synthesis, a specialist in the field of solid-state chemistry and membrane technologies, Chairman of the Russian Membrane Society, and Editor-in-Chief of Membranes and Membrane Technologies journal.

– Andrey Borisovich, could you tell us what your Institute of General and Inorganic Chemistry lab does?

– The laboratory is engaged in several areas at once. First, the materials for energy and environmental technologies. One of the main topics is related to ion-exchange membranes. Membranes are widely used not only in the energy sector, but also for water treatment, separation processes, membrane catalysis, and so on.

There are only a few companies that produce membranes. For a long time, nothing new appeared in Russia, and all the technologies were developed on those membranes that existed in industrial production. In Russia, there were two main technologies for the production of ion-exchange membranes – heterogeneous and perfluorinated homogeneous. Now we have developed several new approaches to the synthesis of ion-exchange membrane materials. In terms of the ratio of conductivity and selectivity, our membrane materials are at the level of the leaders – the perfluorinated membranes, which are extremely expensive and therefore used only for fuel cells.

– This is one area that you are engaged in; what are the others?

– The second direction is lithium ionics. Now everyone has a mobile phone in their pocket, there are cameras, laptops, and so on. All of them have a lithium-ion battery. The capacity of lithium-ion batteries is determined by electrode materials, cathode, and anode, the development of which is the second direction of our laboratory.

For example, if you remember how long it takes to charge a mobile phone or a wireless tool, usually it takes several hours. We have developed such materials, cathode, and anode, which can accumulate and discharge half of their capacity in five minutes while maintaining all the other parameters.

These are the energy-intensive technologies that are required today, for example, for cordless drills, for transport. In fact, they should serve as energy sources when this energy is not enough: when you need to start a car, accelerate it, and so on.

There is an electrolyte layer between the cathode and the anode in the battery. This is the same membrane, but now they are gel containing an organic solvent and lithium salt with a large anion. The problem with these electrolytes is that lithium dendrites can grow through them, which can lead to a short circuit. If we want to quickly charge or discharge a battery, it will inevitably heat up and may catch fire. There were a lot of such cases in the past, there are enough photos of laptops on the Internet that burned down due to a battery fire.

– Have you managed to create batteries that are not explosive, do not burn, and at the same time are energy-intensive?

– Yes, modern devices virtually eliminate this hazard. I was talking about electrode materials. The energy intensity of batteries is determined by cathode and anode materials. The electrolyte is the layer that determines the Coulomb losses and the safety of the battery.

Another very big issue with lithium-ion batteries is that in the cold they discharge extremely quickly. But you come home, and in a couple of minutes, it has almost a full charge. This happens for one reason – the electrolyte freezes, and its conductivity drops sharply, primarily due to the phase transition.

– Does heat also cause such an effect?

– In the heat, there are other effects. Fires and depressurization of the battery become more common. If the organic matter starts to evaporate, this could also be extremely unpleasant.

We are currently developing such electrolytes that have high conductivity and no phase transitions in them. The Nobel Prize Winner John Goodenough believes that if we switch to such electrolytes, the power of lithium-ion batteries will increase 2–3 times over the next few years.

– How do these electrolytes differ from traditional ones?

– There are two main types of electrolytes. The first is polymer electrolytes: for example, when we take an ion-exchange membrane, convert it into lithium form, and fill it with a mixture of solvents that does not freeze at relatively low temperatures. Since all this still occurs due to the swelling of the membrane, the solvent enters the nanopores, the size of which is only four to five nanometers, and its freezing temperature decreases.

Nikolay Leskov once wrote about a Lefty who shod a flea. We often do more or less the same in our scientific work. In the nanopores of the membrane, which are four to five nanometers in size, we synthesize even smaller nanoparticles of inorganic substances so that the transfer in these membranes becomes faster, more selective.

– This is the first type of electrolyte; and the second type?

– The second type is completely solid electrolytes that are based primarily on phosphates. We make solid electrolytes that conduct through lithium ions. Bonds in solids are usually stronger, and their temperature-related conductivity changes only in accordance with the Arrhenius equation. In the foreseeable temperature intervals, this is a relatively small drop. The main thing is to get an electrolyte that conducts current at room temperature.

– What makes your work unique? Is there anything that isn’t done in other global laboratories?

– All the materials that we develop are new. But I can’t say that what we do is completely unique. Many global laboratories are engaged in this. The same Goodenough laboratory, many of my colleagues from Europe and China. Nevertheless, we have made such radiation-grafted membranes that are unique in their own way in terms of the conductivity-selectivity ratio.

– What do you mean by “radiation-grafted membranes?”

– It means that we take a certain industrial film – for example, from polyethylene – activate it, and then synthesize an organic polymer on it, which is then sulfonated. Due to this, we get an ion-conducting membrane.

In ion-exchange membranes, pores are created due to self-organization processes. I don't really like it when people talk about self-organization, because they often speculate on this. It reminds me of a Russian folk tale about Ivan the Fool, who sat on the stove saying, “I want this, I want that,” and got everything right away.

– Everything got organized on its own.

– There is no such thing in science. In science, you must work hard to achieve something. But there is a small exception here when we can get the material to organize itself.

What makes these homogeneous ion-exchange membranes so good? The system is quite simple – there are polymer chains, either hydrocarbon or perfluorinated. But they are all hydrophobic. And there are sulfo groups. You have probably seen such experiments when sulfuric acid is dripped on some kind of wooden coating, and it begins to carbonize. It’s getting charred not because sulfuric acid is a strong oxidizer. It’s not an oxidizer, it just has a very high ability to take water from wherever it is, even from wood. It’s because wood is a carbohydrate, and it actually consists of coal and water. Only that oxygen and hydrogen are combined with the same carbon.

Sulfuric acid can pull water out of anything. When we sulfurize the membranes, we get the same fragments of sulfuric acid in them, which, since they are hydrophilic, combine into clusters. And these clusters suck water from the entire surrounding space. And due to this, pores are formed in the membrane. Due to the fact that these pores are connected by channels, they provide flow-through conductivity in an aqueous solution containing protons of acid residues.

The good thing about perfluorinated membranes is that their entire matrix is completely uniform. But these membranes are extremely expensive, and therefore for all technologies, except for fuel cells, other heterogeneous membranes are used, which are obtained in a much simpler and more suitable way for the industry. This is, actually, the pressing of ion-exchange resin and polyethylene grains, which act as a binder so that such a membrane does not disintegrate. Such membranes are much cheaper. But there are pores between these particles of the ion-exchange material and polyethylene. They are also small, but they are much larger than the pores that are inherent in the membrane itself and determine its proton conductivity.

In the pores, positively charged particles (protons) line up next to negatively charged anions bound to the matrix. Other negatively charged particles are almost completely displaced from the membrane due to Coulomb’s law. But in large pores located between particles, at large distances, these laws do not work, and anions enter and move into them in the same way as protons. In fact, the selectivity of heterogeneous membranes, which are cheaper, turns out to be much lower.

– Andrey Borisovich, could you tell us if you have managed to implement your developments somewhere?

– I guess, all scientists try to implement their developments. My first implementation experience was at the light advertising factory, which produced phosphor lamps. And they are in no way related to what I’m talking about now. We have managed to develop a technology which would make it possible to apply a phosphor coating on the tubes of fluorescent lamps without an organic solvent. We had an agreement with the plant’s management, and even joined forces with them so that our discovery would not be “squeezed,” and found a way to apply the same coatings from an aqueous solution.

We were told that we had done a great thing, we were even paid crazy money at that time, which, thanks to the Pavlov Reform, reduced to dust literally in a matter of weeks. But at this plant, we were told that we cannot introduce it into production, because for that we must stop production for at least four months. But no one will let us do this – we need to fulfill the plan. And the women who worked in this shop and retired at the age of 30 nearly punched us for trying to deprive them of this opportunity.

– And have you had a more successful experience of implementing your developments?

– Yes. Then there were quite a lot of such attempts. Currently, together with our colleagues from Kuban State University and with the Membrane Technologies company, which is headed by Professor Zabolotsky, we produce electromembrane desalination devices.

Together with colleagues from Voronezh State University, we use hybrid membranes with embedded nanoparticles of inorganic substances to produce multi-sensory systems: the so-called electronic nose or tongue. By increasing selectivity due to this, we have made such multisensory systems that allow us to analyze quickly and reliably, for example, the composition of wastewater, medicines, or narcotic substances.

Based on these membranes, our colleagues have made sensors that allow us to determine the freshness of such different products like beer or milk.

We are quite closely engaged in fuel cells. We have recently adopted a program for the development of hydrogen energy in Russia. We are not the first ones in this sense. Such programs have been adopted in many developed countries. And our membranes work well in such fuel cells.

All this is important in the light of the Paris Agreement, which will lead the world to a carbon-free economy. In Russia, the main income is provided by oil, gas, and, perhaps, metallurgical processes, where you can’t manage without coal. Therefore, I’m afraid that if we don’t introduce new technologies, we will face quite difficult times. Another thing is that we need to think in advance about what we should do and how we should do it. It is unlikely that we could rely only on producing hydrogen and selling it abroad. This is primarily embedded in the concept of the development of hydrogen energy in Russia, unlike all Western countries. If this hydrogen is produced from natural gas, it is unlikely that it will be bought.

The whole world is now betting on renewable energy, which is based on solar batteries, wind turbines. And with them, energy storage devices, for example, batteries, should be paired. But it is impossible to believe that these will be lithium-ion batteries because the reserves of lithium on Earth are small. And for large-scale energy, huge quantities are needed. For large-scale energy, it will be almost one hundred percent replaced by sodium.

During the sunny hours, for example, we accumulate energy in lithium-ion or sodium-ion batteries. We can get hydrogen by electrolysis, and then, when we need it, we can get the energy we need from this hydrogen or from lithium-ion batteries. If we talk about the day-night cycle, these are batteries. And for the summer-winter cycle – hydrogen.

There are already a lot of hydrogen-powered cars and buses in the world. This is where we are going. Russian Railways have committed to developing a hydrogen-powered train.

– Are we moving towards saving resources, using them in such a way that nothing is wasted?

– This is on the one hand. And on the other hand, when we talked about the Paris Agreement, we talked about global CO2 emissions. But in fact, there are not only CO2 emissions. If we think about where harmful substances in the atmosphere come from – most of them are from vehicle emissions. These are the products of incomplete oxidation of gasoline, nitrogen oxides. One could think, why would they be there? But in fact, the oxidation occurs with air, and therefore, perhaps not to such a significant extent, but still, the nitrogen of the air is combined with oxygen. There is a sulfur compound in fuels as additives or impurities, which means that emissions of sulfur oxides also occur.

But we live in a megalopolis, in a huge city, with many cars and various enterprises. If we introduce hydrogen-powered transport at least in the city, we could dramatically improve environmental quality. At the same time, somewhere there will be factories that produce hydrogen, and this production will not be very clean. However, we can spread it in the atmosphere in such a way as to minimize the damage to humanity. Taking care of megacities is also a very important component of all these technologies. Maybe there is much less talking about this, but it is no less important because it is a real concern for people. In fact, while hydrogen energy is quite expensive, science does not stand still, technologies are being improved, and the desire to fight for the environment gives them an additional impetus.

Interviewer: Natalia Leskova

Photos: Nikolay Mokhnachev

Video: Alexey Kornoukhov