Scientists from the Industrial University of Tyumen (TIU) are demonstrating original analytical and numeric methods that can be used to ensure serviceability of tanks and various work process units with combustible materials. The methodology they demonstrated allows calculating mode of deformation for a broad range of loads and impacts, and developing an algorithm for making the decision whether the tanks are in need of repair. This approach would help oil production and processing companies avoid accidents and thus losses and harm to the environment

Large amounts of organic combustible material – oil and gas – require high-quality and reliable storage and equipment operation. Otherwise, there is a risk of an environmental disaster, and the subsequent protracted period of recovery of natural resources. This is why there are various maintenance activities and repairs undertaken to ensure safety. In addition, theoretical and practical methods of diagnosing and forecasting equipment serviceability parameters are developed with the use of mathematical models.

TIU specialists, adhering to the tank deformation limits, calculate sedimentation progress and permissible stress in the structure in order to determine the nature of deformation of the objects in question.

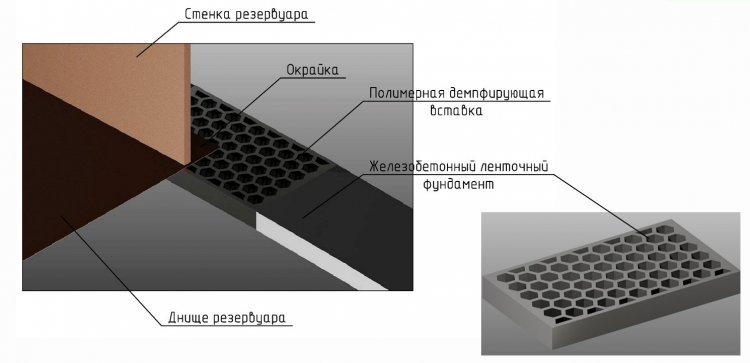

Scientists are also working on seismic stability of oil and gas storage facilities, offering a proprietary methodology for seismic stability assessment of tanks.

Pyotr Vladimirovich Chepur – Candidate of Engineering Sciences, Docent of the Department of Applied Mechanics at the Transport Institute of the Industrial University of Tyumen – spoke of the advantages of an innovative solution, which is based on numeric calculations and aimed to make oil&gas facilities more efficient and safer.

“As a complex and capital-intensive technical system, the infrastructure for trunk oil&gas transportation can pump millions of tons of oil and billions of cubic meters of gas per annum.

Thus, structures, mechanisms and process equipment are being heavily used, which leads to constant wear and tear. Given the high pressure and volumes of the hydrocarbons being transported, accidents may occur and cause a disaster: many millions worth of material losses, damaged environment, and even loss of life. Serviceability issues on such facilities arise from a number of causes, such as: changes in geological, hydrogeological and climate parameters of the site over time; changes in the legal framework; sometimes, excessive pressure on infrastructure – beyond the original design parameters; mistakes during construction and installation, and hidden defects. All of these factors reduce the service life of pipelines and storage facilities. When analyzing the reliability of facilities that have been in operation for a long time and suffered some wear and tear, the specialists have to decide whether to dismantle the existing facility and organize new construction or to consider extending operation through reconstruction or rehabilitation. This is the stage where the scientific agenda our team has been working on becomes relevant,” said Pyotr Chepur, outlining the existing issues of serviceability of oil and gas transportation and storage facilities.

The Industrial University of Tyumen has an established scientific school “Serviceability of oil and gas transportation facilities” led by Professor Aleksandr Alekseevich Tarasenko, Doctor of Engineering Sciences.

“I’ve been afforded the honor of continuing the traditions of the scientific school of Professor Aleksandr Alekseevich Tarasenko. Back when I still was his pupil, I was able to defend my Candidacy thesis, publish over 150 joint scientific works, index both in the Russian scientific base of the Russian Science Citation Index, and in the international systems SCOPUS and Web of Science. In 2019, the monograph Investigating development patterns of differential settlement of tanks by numeric methods was published by Nauka publishing house and received “top marks” from experts of the Russian Academy of Sciences,” says young scientist Pyotr Chepur, proud of these achievements.

The monograph that won high appraisal from RAS experts

What are the main focus areas of the school?

“The main focus areas of the scientific school are: tasks related to strength calculations for metal structures of pipelines and tanks; assessment of mode of deformation of tank structures in an extraordinary operation environment; improving seismic stability of oil storage facilities and LNG tanks,” the researcher said.

Which scientific schools are your partners or competitors?

“We keep in touch and cooperate on issues relevant to our agenda with: the National University of Oil and Gas “Gubkin University” (Moscow), Ufa State Petroleum Technological University (USPTU)(UFA), Samara Polytech Flagship University (SamGTU) (Samara), and China University of Petroleum (Qingdao),” Pyotr Chepur detailed.

TIU specialists offer their own solution for the problem of serviceability of oil and gas transportation and storage facilities.

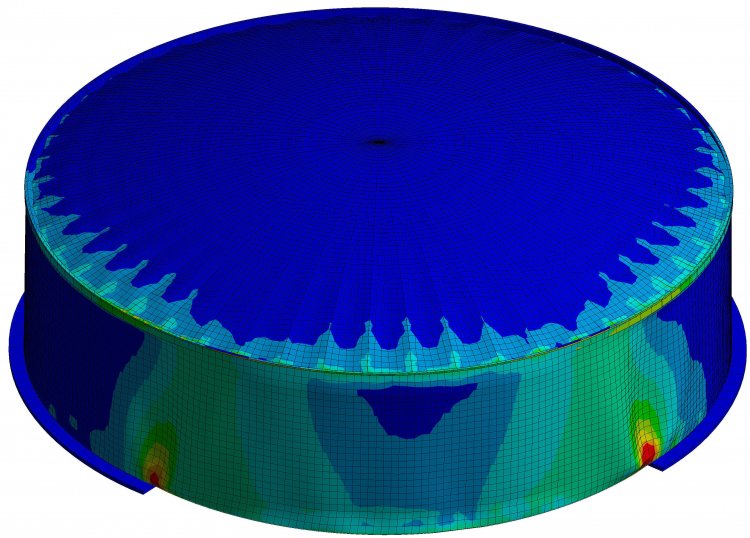

“This is a scientific approach involving highly detailed computer-based modeling (based on finite elements method – FEM) of any facility of interest. Essentially, we are creating a digital double of the structure and its operation environment, and use high performance calculations done by a digital model to determine the remaining service life and check strength, stability and fatigue of metals. Moreover, our task is to create universal engineering methodologies based on scientific work performed, which process technology offices could apply. The next stage is updating existing technical regulations and drafting new ones for both agency and federal levels,” the young scientist explained.

According to Pyotr Chepur, the effectiveness and reliability of the proprietary product is in “the accuracy of the end solution and the possibility of visualizing the result in a 3D model. The high level of detail and the visualization of the solution for an engineering problem allows, for instance, evaluating the distribution of stress and deformations over the entire model (rather than for an individual assembly) within one calculation. This approach makes missing dangerous zones (or “bottlenecks”) far less likely, while with lower level of detail such zones might simply be missed and not included in the final report.”

Image 1. Finite-element model of a tank created within the study of differential settlement

In addition, the Tyumen researchers have analyzed seismic stability of oil and gas storage tanks by applying response spectrum analysis and the direct travel time method with the building of highly detailed models (digital doubles) of structures.

Pyotr Chepur believes that “the capacities of computing systems have recently reached a level allowing us to look at physical modeling problems in a new way. The level of detail of the geometry of structures is a significant factor in the accuracy of the resulting calculations, as well as the correct recording of acting loads and contact and boundary conditions.”

Has your approach been tested on facilities in any seismic zones?

“I would like to point out that, after all, we follow the existing international and Russian regulations on design and construction in highly seismic zones. Therefore, as source data, we are normally interested in potential seismic activity of 6, 7, 8 and 9 points (as per MSK-64). Geographically, this primarily means countries of South-East Asia, the Far East and the Caucasus. The analysis is mostly focused on high-capacity LNG tanks and vertical steel tanks for storage of oil and oil products,” the scientist clarified.

Image 2. The proposed model of a damping insert increasing seismic stability of the tank.

Are there supporters/stakeholders in your products? Where are your approaches ensuring serviceability of oil and gas transport facilities introduced?

“We are actively cooperating on research on seismic stability of oil&gas industry structures with China University of Petroleum in Qingdao, which has a well-established team led by a professor and consisting of post-graduate and undergraduate students whose scientific interests are focused on methods to increase seismic stability of LNG tanks. Before the COVID-19 pandemic, we used to organize joint meetings and master classes, make presentations at conferences, and hold modeling master classes for Chinese post-graduate students; we have performed several experiments on real structures. However, the pandemic forced us to limit this work to the remote format.

Russian companies are also interested in the continuation of our scientific efforts in the serviceability area. For example, we have received the implementation report on our Deformation Mode Assessment Methodology for Tanks with Differential Settlement of the Base. A trunk oil transportation company continues using this methodology and the approaches we proposed in diagnostic and repairs of large vertical steel tanks,” Pyotr Chepur revealed.

The alternative way of assessing serviceability of oil and gas transport and oil facilities, proposed by the Industrial University of Tyumen (TIU) can justifiably be introduced to assist companies of the oil&gas industry in managerial decision making.

All photos and pictures are provided by Pyotr Chepur

Photo preview lush