It is currently impossible to print a full-fledged human organ in such a way as to implant it: replace, for example, a heart or liver. Neither in Russia nor abroad the technology has matured. The immediate goal is to print individual fragments of organs or tissues accessible to society.

Photo: Andrey Luft / Scientific Russia

One of the methods is the use of additive technologies – 3D printing – with materials that contain living cells. “This is a difficult path. As a result of printing, the stress of cells is possible and, accordingly, a change in their vital activity and functions,” says Natalia Menshutina, Professor, Head of the Department of Chemical and Pharmaceutical Engineering at D. Mendeleev University of Chemical Technology of Russia.

Young specialists at UCTR follow a different path – the creation of matrices. These are porous frameworks of the desired shape, into which specific cells are introduced, after which transplantation into the body is carried out. Time passes, and the porous framework is destroyed – when the cells are fixed in the body, it is no longer necessary. The matrices obtained using this technology can be used in biotechnological processes to increase productivity and efficiency. In addition, the use of matrices with complex geometry as highly effective implants is promising. This budding technology is being researched in many countries and the urgent question is who will be the first to achieve results that can be disseminated in medical practice.

In a laboratory of the University of Chemical Technology of Russia

Photo: Andrey Luft / Scientific Russia

Material

The implanted matrix should be biocompatible with the body, not cause an immune reaction. At the same time, over time, it should biodegrade – dissolve without residue, and be available during production.

At UCTR, a sodium alginate-based material is used to create matrices – this material is obtained from brown algae, for example, sugar kelp. The technology is available, proven, and safe: sodium alginate is used in the food industry as a thickener and stabilizer, and in medicine as an antacid – a drug for the treatment of acid-dependent diseases.

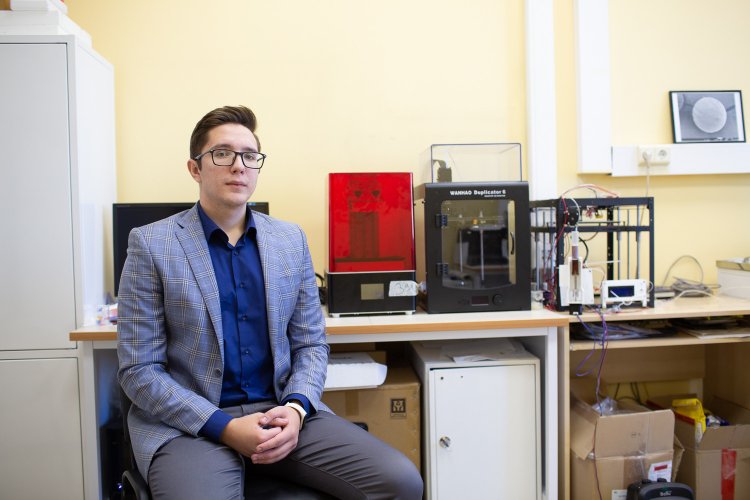

The sodium alginate-based material is obtained as light as possible after drying, with a porosity of up to 95%. And it is suitable for the manufacture of matrices with specified parameters: it does not cause an immune reaction, and dissolves over time: “It was important for us to choose both the concentration of sodium alginate itself in solution and the optimal concentration of the crosslinking agent. We used a classic version of crosslinking by ion interaction, using calcium chloride. Calcium chloride is injected into the sodium alginate solution. Selecting different compositions, we varied the viscosity and, depending on the selected composition, the material showed thixotropic properties in different ways,” Pavel Tsygankov, Candidate of Technical Sciences, told us about the composition of the material for the manufacture of matrices.

Pavel Tsygankov

Photo: Andrey Luft / Scientific Russia

In the classical scheme of plastic 3D printing, the thread of the material is heated up, becomes elastic, and in this state, layer by layer forms the object, hardening when cooling. When bioprinting, new approaches are needed: in particular, the thixotropic properties. The material – this its feature – becomes less viscous under the mechanical influence and thickens at rest. That is, when pressed, the substance becomes liquid enough to pass through the nozzle of the extruder (pushing device) of gel materials but thickens and does not spread once on the surface where the product is formed. You can apply layer after layer.

It is not only thixotropic properties that determine the suitability of the material for 3D printing. Special attention should be paid to the properties of the final product. Studying the required properties, research is carried out to obtain various composite materials for the implementation of 3D printing. “We research various combinations of materials to increase the survival of cells on these carriers or to impart the necessary properties. For example, blood vessels should be elastic and have a certain coefficient of stretching and compression.

We came to the production of alginate-gelatin and alginate-chitosan composite materials to achieve the necessary stretching and compression index. Materials based on gelatin alginate are elastic enough for production. Now we are selecting concentrations to print with this material,” said Andrey Abramov, an employee of the Department of Chemical and Pharmaceutical Engineering.

Andrey Abramov

Photo: Andrey Luft / Scientific Russia

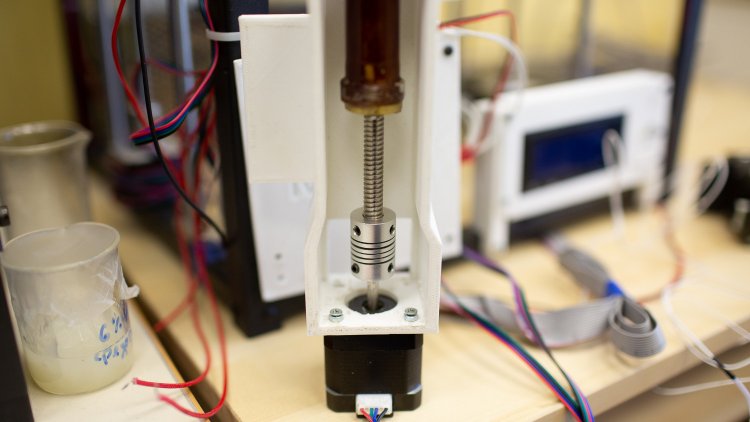

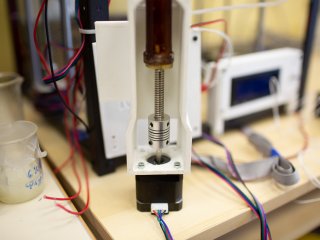

Printer

Pavel Tsygankov and Andrey Abramov work with a Flyingbear p905 3D printer in a small laboratory of the University of Chemical Technology of Russia. However, only the base – frame, guides, and mechanisms for moving the printer head, the surface on which the product is formed remained from the main device. The remaining elements – the punching machine and nozzles for the extruder of different diameters – were supplied anew.

The software part of the printer was also replaced – the new software controls all the actions of the 3D printer: the material feed rate, the extruder system, the carriage movement parameters. Everything suitable for printing with plastic is not suitable for working with new materials. Choose incorrectly the speed of application of layers or the force of pushing through the raw material – and the material will either spread or clog the nozzle of the extruder. Among themselves, young scientists call the composition used to print matrices ink, although not everyone likes it – “gel materials for printing” sounds better.

The printed blanks are sent to dry. After gel printing, the object receives a formed structure, but liquid remains in its pores. It is important to extract the liquid, but to preserve the nanoporous structure. To do this, supercritical drying is used, which avoids the formation of menisci inside the pores. In hydrostatics, a meniscus is a curvature of the surface of a liquid when it comes into contact with the surface of a solid. With supercritical drying, capillary forces do not squeeze the pores and the structure of the product does not collapse.

“Classical thermal drying is used, for example, in dried fruits – with this method, the original structure is destroyed: under the action of capillary forces, the pores shrink, and the material becomes rigid, as a result, the dried fruits deform. To avoid this, we use supercritical drying, supercritical carbon dioxide. It mixes with the solvent inside the pores of the gel and is gradually extracted. After we relieve the pressure, the supercritical carbon dioxide inside the pores turns into a gaseous state and we get dry objects,” Pavel Tsygankov talks about the process.

Photo: Andrey Luft / Scientific Russia

Photo: Andrey Luft / Scientific Russia

Perspectives

There is equipment for 3D printing. There is a material with which the printer can work, producing matrices of suitable quality. Ahead lies the research of development prospects together with partner institutions, that has already been launched.

The results of the initial tests on the saturation of manufactured matrices are not yet being told at the UCTR – yes, work is underway, and there are certain achievements. But they are not in a hurry to publish the information definitively, it takes time. According to optimistic forecasts, in a year something they expect to start experiments with implanting matrices on animals, but these are expensive experiments, it is impossible to say exactly when the research will begin.

Natalia Menshutina, Head of the Department of Chemical and Pharmaceutical Engineering at D. Mendeleev University of Chemical Technology of Russia, says that in general, the society will see achievements in the field of medical additive technologies with a delay – many developments are directed to the defense sector, technologies are closed to the masses. But there are prospects, and the possibility of their practical application can be assessed right now, printing tissues and organ fragments is a direct path to deeply personalized medicine.

“Heart valve replacement surgeries are taking place today. These heart valves are either taken from pigs and implanted after cleaning or taken from donors. Our university is developing heart valves based on biopolymers – several people already have such valves. Therefore, it is possible to replace individual parts of the heart, but time will tell whether it is possible to replace the whole heart. Today, scientists agree that the most complex organ is the liver: it is permeated with vessels of various sizes, and it is very difficult to repeat this when artificially creating an organ. Although today information technologies allow using computed tomography to translate a human organ into a 3D computer image. So, it can be printed. I think that everyone will try to break through to the printing of the heart,” Natalia Menshutina notes.

Natalia Menshutina

Photo: Andrey Luft / Scientific Russia

“Personalized medicine is needed for the prosthetics of human tissues and organ fragments. Each person has their own geometry of internal organs and tissues. Based on medical research, computed tomography, and MRI, a model of a specific organ or tissue is created. I will explain by the example of a vessel – it is possible to identify the area most susceptible to deformations, the formation of an aneurysm, the destruction of the vessel wall, which leads to internal hemorrhage. Calculating these areas using mathematical modeling methods, it is possible to print and replace them,” says Pavel Tsygankov.

These are prospects and now it is unclear how far away. But a prototype of a carotid artery section of a particular person at risk of an aneurysm has already been translated into a mathematical model and printed taking into account personal geometry. Now it is being tested for cytotoxicity and suitable mechanical properties.

“Additive technologies are the most promising way to personalized medicine. So far, no technology allows us to move so quickly from a prototype to a finished product. There is no need for intermediate components: for example, molds that are used in molding,” says Andrey Abramov.

It is not yet possible to print a full-fledged human organ. Technology has not matured. At least, there is no system that for this purpose would combine all the achievements of materials science, chemistry, biology, physics, mathematics, and computer modeling, including their specific branches. But some studies show the prospects of the approach and, maybe, over time, a full-fledged term Additive Medicine will appear.